Predictive model to improve electric vehicle fleet management

Leading factories and warehouses have internal traffic resembling that of cities, including fleet of taxis for point-to-point automatic transportation. These taxis are known as ‘automated guided vehicles' or AGVs and have become increasingly popular.

Transportation systems based on autonomous vehicles can adapt to the changing needs of every moment, even without any central control. For example, auctioning transportation orders among all available vehicles is a way to facilitate the one with the best bid to pick the material at the collection spot and deliver it to its destination with the least possible cost.

Typically, AGVs are powered by batteries. As the load of the batteries affects their speed significantly, the time required to carry out a transportation order not only depends on the distance to be travelled but also on the available energy.

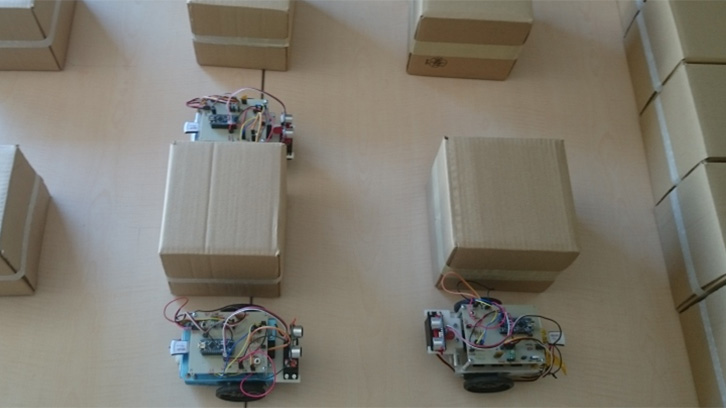

In this work, we have set up an experimental and scaled plant to study the relation between the charge of the batteries and the time required to carry out a given transportation order. Approximate expenditure of energy for each operation can be foreseen using the model derived from this study. Thus, it is possible to estimate the time needed for each operation, which is more accurate than that derived from theoretical or heuristic models. Experimental results show that the costs of operation can differ up to 25%, depending upon the model. Hence, the use of the new model can significantly improve the planning of the routes, in order to minimize the service time for each operation as well as to optimize the management of the batteries.

This model can be extended to full fleets of electric vehicles to increase the reliability of the predictions and improve the overall efficiency of corresponding transportation systems, not only in factories and warehouses, but also in urban areas.

Department of Microelectronics and Electronic Systems

Universitat Autònoma de Barcelona

References

Pragna Das, Lluís Ribas-Xirgo. A Study of Time-varying Cost Parameter Estimation Methods in Automated Transportation Systems based on Mobile Robots. 21st IEEE International Conference on Emerging Technology and Factory Automation. September 2016 DOI: 10.1109/ETFA.2016.7733679